.jpeg?width=300&name=ds-ns-advanced-manufacturing%20(4).jpeg)

Optimise Your Manufacturing Processes with NetSuite

Empower your production management with real-time manufacturing analytics, advanced automation, and seamless integration. Whether you require light assembly, WIP tracking, or a full-scale manufacturing execution system (MES), NetSuite offers a solution tailored to your needs.

NetSuite provides three flexible manufacturing solutions, allowing you to choose the right fit for your business and seamlessly upgrade as your needs evolve.

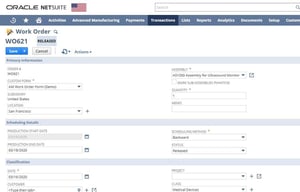

NetSuite can be easily configured to support the needs of manufacturers of all types and sizes, and for many the first step is to implement the Work Orders and Assemblies module. Enabling this feature allows users to define assembly items, build complex multi-level bill of materials, create work orders, record assembly builds, and backflush components with minimal effort.

In NetSuite, an Assembly Item is a manufactured product that uses other components. It can be defined as lot numbered or serialised for full traceability of components and end products.

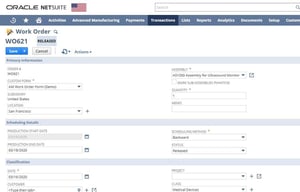

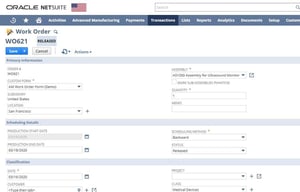

In NetSuite, while creating a Work Order is optional, it becomes essential for communicating production details and managing configurable products. It serves as the foundation for a production control system, with automatic calculation of Actual Production Dates to enhance production planning and decision-making.

The traveler is a printed document for production to convey the plan and report actual raw material usage.

Instructional files can be printed with the traveler for efficient information sharing with the production team.

NetSuite's Work Order creation automatically allocates inventory to production, providing a clearer inventory status.

The Assembly Build transaction consumes components to create the finished product, known as "backflushing," and can be completed with or without a work order.

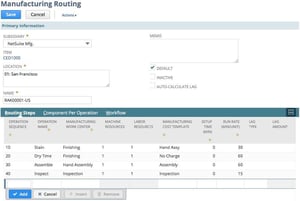

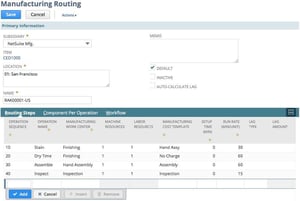

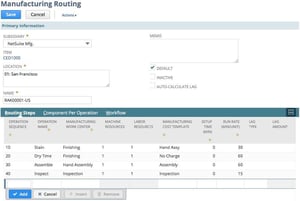

Activating NetSuite’s WIP and Routings features allows companies to establish a routing for the manufacturing process, detailing the resources required to complete it, along with the anticipated time and cost. Routings also serve as the foundation for the infinite capacity scheduling engine, which can pinpoint resources that are either overused or underutilised. Additionally, tracking the cost of materials used during the manufacturing process provides a comprehensive view of the process costs before they are finalised and recorded in the GL.

The manufacturing cost template outlines the direct and indirect costs linked to an operation's routing, as well as the accounts where these costs should be recorded. Each time an operation is finalised, NetSuite employs the related cost template to establish a foundational framework for product costing, while preserving adaptability.

After defining work center and cost templates, production routings can be established to detail each product step, setup and run times, and associated costs, aiding in real-time scheduling that can be adjusted as needed.

The Work Order Traveler outlines the production plan, routing steps, and schedule, while also tracking operation times and material usage. The Dispatch List details the materials needed for a work order.

NetSuite allows for flexible manufacturing processes, enabling different production methods and cost tracking at each location.

Before defining the manufacturing process with routings, set up the work centers, which can be machines, people, work cells, or departments, as they are crucial for the real-time scheduling engine.

The WIP Issue transaction manually allocates materials to the Work Order—and into WIP—as they are utilised. This is particularly beneficial for manufacturing products that require extended completion times and have multiple work orders open at month-end.

The WIP and Routings module enhances control and visibility over work orders by adding statuses like Open Planned, Firm Planned, and Released. It allows production controllers to efficiently manage and update these statuses through mass update screens and an automated workflow engine.

NetSuite Advanced Manufacturing provides a unified cloud solution that replaces the fragmented systems currently used by manufacturers. It features extensive functionality and is specifically crafted to assist manufacturers of all sizes in lowering operating costs, boosting revenue, and enhancing the management of their business and supply chain processes. Built on the native NetSuite ERP, NetSuite Advanced Manufacturing ensures that manufacturing processes are seamlessly connected to financial reports, inventory management, and outstanding orders in real-time.

.jpeg?width=300&name=ds-ns-advanced-manufacturing%20(4).jpeg)

NetSuite offers a robust, vertically-integrated solution designed to assist manufacturers in managing their operations more profitably, from Order-to-Cash to Build-to-Ship. With NetSuite’s Advanced Planning and Scheduling features, customers can efficiently organise their shop floor, enhance capacity and resource utilisation, and ultimately reduce operating costs.

NetSuite Advanced Manufacturing offers comprehensive solutions for Discrete/Assembly and Batch/Process Manufacturers, providing industry-specific functionalities like configurable work orders, enhanced data collection, and detailed work instructions. It supports advanced planning, scheduling, and execution capabilities, including bar code-enabled Shop Floor and Batch Travelers, ensuring efficient operations and full traceability.

NetSuite's mobile features enable real-time MES reporting with bar code scanning and wireless tablets for tasks like data entry, work order completion, material issuance, downtime, and labor or machine hours tracking by employee ID.

Efficiently managing a manufacturing business involves controlling work orders and processes, which can be optimised using the Advanced Manufacturing Admin Console to configure NetSuite for your specific needs.

NetSuite offers three manufacturing deployment options: Work Orders & Assemblies for light assembly needs, WIP & Routings for more detailed tracking and scheduling, and Advanced Manufacturing for comprehensive process control. Each option can be upgraded seamlessly to suit evolving manufacturing requirements.

Enhances capabilities for discrete and assembly manufacturers.

- Establish detailed work instructions

- Link material consumption

- Evaluate resource supply against demand

- Track downtime and losses

- Adapt work order processing for your specific locations

- Gather and organise essential shop floor data

- Improved BOM and Work Order release

- Work Bench Record Structure

- Customisable Shop Floor and Batch Travelers

- Rough-Cut Capacity Planning

- Dynamic Scheduling Code

- Finite Production Planning and Scheduling

Key Benefits

Ensure your production processes run smoothly and efficiently.

-

Enhance operational efficiency and reduce the cost to produce

-

Capture real-time production updates directly from the floor

-

Foster continuous improvement with scrap and downtime reason codes

-

Boost user satisfaction and data precision with a unified solution - reduce the reliance on third parties

-

Precise COGS calculation

-

Facilitate seamless two-way communication with the production floor

-

Establish a well-defined manufacturing process

A Single, Unified Solution to Drive Manufacturing Excellence

.jpeg?width=300&name=ds-ns-advanced-manufacturing%20(4).jpeg)

.jpeg?width=300&name=ds-ns-advanced-manufacturing%20(4).jpeg)

How businesses are benefiting from NetSuite

“To give you an idea, a previous stock take resulted in a write-off of $60,000. The most recent one had a miniscule variance of a few hundred dollars.”

"Project Salsa has provided excellent support, second to none. They see themselves as part of our business, and that's been fundamental in getting the best outcome."

"And with NetSuite, we’re now able to pinpoint and addressing any processing gaps, with line-by-line visibility which means we can introduce controls accurately where necessary."

"There are things you need to figure out with every ERP project, but with the right partner, that’s just part of the job; Project Salsa has demonstrated an ability to think through the processes and put in the time and effort to get where we need to be."

"That scalability is comforting. It means we just put in the connectivity and replicate it.”

"I would choose them time and time again. They might be NetSuite specialists, but if they could handle every software implementation going forward, they would be the choice. The support is amazing, they are always available, and they are always working to make our NetSuite better."

"Already, we’re seeing greatly improved visibility across the purchase-to-pay side of things. The built-in dashboards give a good feel for where we are with invoicing and purchase orders, and we’re getting the benefits from built-in and integrated workflows which were absent in our previous setup where we had to jump in and out of different systems.”